QRA MODEL

Integrity Plus has nearly two decades of experience providing quantitative risk models to the pipeline industry. Our algorithms are curated from best practices gleaned from hundreds of technical documents, adapted to available data sources, and joined into a single cohesive structural reliability framework.

This model runs on New Century’s Spatial Risk Analyst platform, allowing it to consume and integrate a wide variety of data to support information analysis and risk assessment. Some key categories of data consumed by the model include:

- Pipe Material Properties

- Product Characteristics

- Operating Conditions

- Environmental Conditions

- Pipe and Coating Condition Assessments

- Engineering and Corrosion Management Surveys

- Cathodic Protection Data

- Population Impacts and Encroachment

- Natural Hazards

This information feeds algorithms that create a digital twin of the pipe and its environment. The current and future condition of the pipeline is modeled along with the consequences of a potential failure to estimate risk.

The outputs of our model are quantifiable and verifiable units of risk (in $/yr or $/mi-yr) that can be used to make integrity management decisions with confidence.

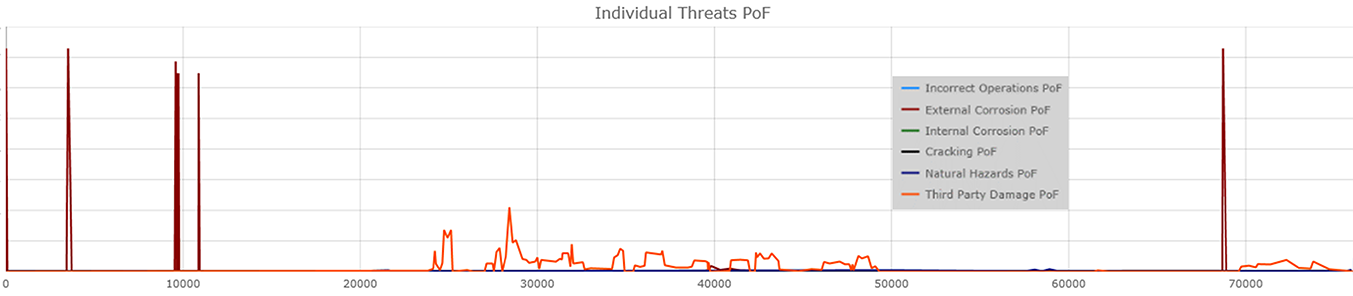

- Identify potential pipeline integrity threats

- Zero in on the highest-risk areas

- Focus on what’s driving risks higher

- Evaluate risk reduction using “what-if” analysis and mitigation planning

- Produce reports, maps, dashboards, and other visuals to communicate and document findings

Designed for transmission pipelines, the model is also suitable for gathering and distribution systems with adequate data to support quantitative risk.

While this mature model produces exceptional results and has passed many regulatory audits, perfecting a digital twin is an evergreen process. Integrity Plus is constantly improving the model and updates are offered through a low-cost subscription program driven by customer feedback gathered through our community of practice.

SUPPORTING SERVICES

Our risk team includes diverse skills and experience to support all your risk management needs, including:

- Data collection, consolidation, and preparation

- Adaptation to company data sources, data models, and domain types

- Customization of algorithms

- Verification and validation of model results

- Customized maps, dashboards, and other visualizations

- Risk analysis to develop insights, identify issues, and propose actions

- Facilitating development of company risk criteria

- Integrating risk management within the integrity management process

- Updating Integrity Management Plans

Drive Consistent and Justifiable Decisions

- Produces quantified risk estimates that can be compared to risk tolerance

- Risk expressed as $/yr can be used in cost-benefit analysis

- Number of fatalities/yr is comparable to company or societal risk criteria

- Identify other (risk-based) conditions that should be addressed

- Evaluate prevention and mitigative measures

- Protect assets from further degradation and damage

- Reduce future repairs and extend useful life of the asset

Optimize Spending on Integrity Management

- Identify and target the highest-risk areas

- Determine which prevention measures offer the greatest risk reduction factor

- Analyze benefits of additional remediation to extend assessments intervals

- Evaluate contributions of uncertainty and its impact on the decision process

Maximize System Performance

- Make better Integrity Management decisions

- Eliminate integrity failures to maintain availability

- Reduces operational impact and cost of unnecessary assessments

Our team has curated industry standards and practices into a single cohesive model that includes the following features:

- Fully quantitative model with a probabilistic approach to uncertainty

- Single model addresses both liquid and gas pipelines

- Consequence calculations for jet fire, pool fire, flash fire, VCE, and toxic hazards

- Environmental impacts analysis

- Likelihood estimates based upon sound engineering principles

- Evaluation of interacting defects, co-incident threats, and common risk factors

- Condition assessments data from hydrotest, ILI, and DA

- Multiple types of corrosion and engineering surveys

- Resistance (remaining strength) calculated using fracture mechanics principles

- Adjust conservatism of the model (P50, P90, etc.)

- References included for supporting technical documentation

Compliant with CFR 192 Subpart O (gas) and CFR 195.452 (liquids)

Aligned with the following standards:

- ASME B31.8S – Managing System Integrity of Gas Pipelines

- API STD 1160 – Managing System Integrity for Hazardous Liquid Pipeline

- API 579 – Fitness-For-Service (FFS)

- ASME B31G – Determining the Remaining Strength of Corroded Pipelines

- AGA NG-18 – Ductile fracture properties of selected line-pipe steels

- API RP 1176 – Assessment and Management of Cracking in Pipelines

- API RP 1183 – Dent Assessment and Management